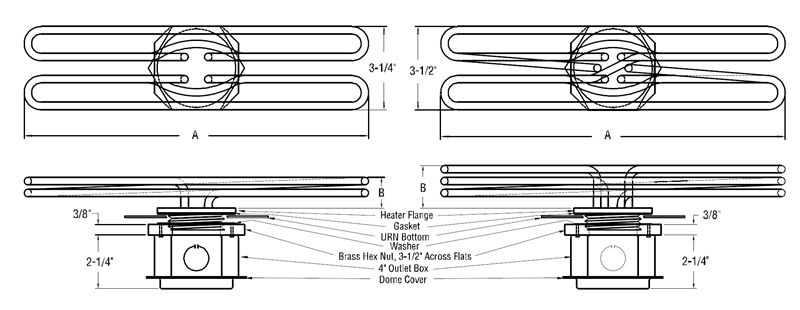

Bottom-Mounted Heaters

Bottom-Mounted immersion heaters were originally designed for use in coffee urns. However, their compact construction makes them ideal for use in steam tables, humidifiers, sterilizers and other applications requiring a very low heater profile and a short element length.

Standard heaters are available in 120, 208 and 240 volts. Heaters with two elements are designed for single-phase operation, while three element heaters can also be used for single-phase applications where space limitations preclude the use of a two-element heater.

Standard Construction

Bottom-Mounted immersion heaters are made with either two or three copper-sheathed tubular elements that are silver soldered to a threaded brass fitting. The fitting is installed through a 2-7/16″ diameter hole in the bottom of the vessel, and secured to the vessel by a brass hex nut. The hex nut is an integral part of the NEMA 1 terminal box, which is standard on all units.

Since standard heaters are made only with copper elements, their use is confined to water or solutions not corrosive to copper or brass. All heaters are designed at a watt density of 50 watts per square inch or less.

Special Features

Allen Head Fitting – For convenience of installation, an Allen head fitting can be furnished on a NEMA 1 outlet box. This allows installation with a 3/8″ Allen wrench rather than the wide jaw wrench required to fit the large hex nut on the NEMA 1 box.

UL Listing – All standard Bottom-Mounted immersion heaters, with or without a low water cutout, are Listed by the Underwriters Laboratories under Reference E23541.