Standard Control Options for Electric Duct Heaters

Heatrex developed the Control Option concept to maintain compliance with changing UL and NEC requirements and to stay current with new electric duct heater temperature control systems. The concept has also been broadened to include numerous “Special Features” to meet a wide variety of special requirements.

Internal Wiring Copper wire with a minimum of 105°C insulation is used throughout. Connections are made with either box lugs or connectors crimped on with calibrated tooling. Terminal blocks are provided for all field control and power wiring. New

Control Option G – Basic Control Option G is a basic package designed for normal comfort heating applications – i.e., those that do not require pneumatic control or the unique features of SCR control. With Option G, the temperature is controlled by a pilot duty thermostat or a step controller. Control Option G includes the following:

- Automatic and manual reset thermal cutouts to protect against overheating. The automatic reset cutout is wired into the control circuit; the manual reset de-energizes the heater load.

- A differential pressure airflow switch to de-energize the heater control circuit upon loss of airflow.

- De-energizing magnetic contactors for each heater stage.

- Fuses to protect each circuit in any heater drawing more than 48 amps.

- A control circuit transformer, with 24 or 120 volt secondary as specified, including any over-current protection required by UL or the NEC.

- A built-in, snap-acting disconnect switch with door interlock to protect service personnel.

Control Option J – Pneumatic Control Option J is designed for pneumatic temperature control. The contractor need only connect one airline and the main power lines to the heater:

- Automatic and manual reset thermal cutouts and a differential pressure airflow switch. The manual reset thermal cutouts always de-energize the heater load. The automatic reset cutout and airflow switch are normally wired in the control circuit.

- PE switches to control heater staging. To minimize field labor, multiple PE switches are factory-piped to a single port projecting through the terminal box. All PE switches close on pressure rise and open upon loss of pressure to de-energize the heater.

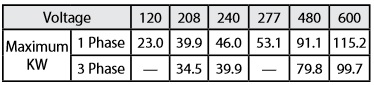

- De-energizing magnetic contactors on all three phase Option J heaters and on single-phase heaters whose KW ratings exceed optimal values.

Control Option K – Proportional Control Option K is designed for the most precise temperature control, using SCR proportional power controllers and a matching electronic thermostat. In addition to these electronic components, Control Option K includes the following:

- Automatic and manual reset thermal cutouts and a differential pressure airflow switch. The manual reset thermal cutouts always de-energize the heater load. The automatic cutout and airflow switch are normally wired in the control circuit.

- Safety magnetic contactors controlled by the automatic reset cutout.

- De-energizing, magnetic contactors.

- Fuses to protect each circuit in any heater drawing more than 48 amps.

- A transformer, with any overcurrent protection required by UL or the NEC, to supply the internal control circuit of 120 volts per heater with a step controller for vernier control and 24 volts for all other heaters with SCR control. Wiring to remotely mounted thermostats can be Class II since thermostat circuits are low voltage limited power circuits.

- A built-in, snap-acting disconnect switch with door interlock to protect service personnel.

From Room thermostats, PE Transducers to Duct thermostats; Heatrex offers exactly what you need.

Our heaters and controls range from the simplest standard duct heater to the most sophisticated, custom designed comprehensive system. Heatrex’s attention to detail and rigorous testing give worldwide customers premium products that they receive quickly and at a fair market price.

For more information on Standard Control Options for Electric Duct Heaters, please contact us at www.heatrex.com or 800-243-8162.