Special Purpose Heaters

Special Purpose Heaters can be designed by Heatrex just for you!

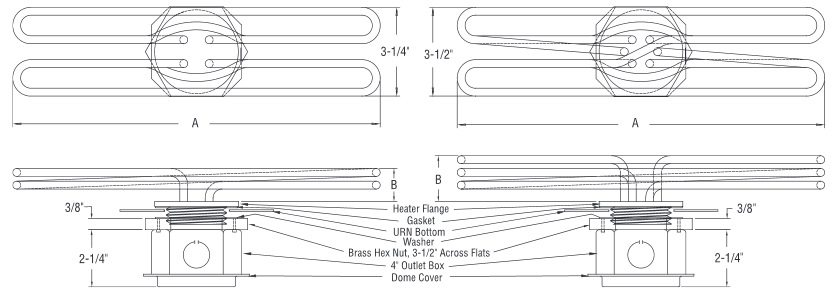

Bottom-Mounted immersion heaters were originally designed for use in coffee urns. However, their compact construction makes them ideal for use in steam tables, humidifiers, sterilizers and other applications requiring a very low heater profile.

Standard Construction Bottom-Mounted immersion heaters are made with either two or three copper-sheathed tubular elements that are silver soldered to a threaded brass fitting. The fitting is installed through a 2-7/16″ diameter hole in the bottom of the vessel, and secured to the vessel by a brass hex nut. The hex nut is an integral part of the NEMA 1 terminal box, which is standard on all units. Since standard heaters are made only with copper elements, their use is confined to water or solutions not corrosive to copper or brass.

All heaters are designed at a watt density of 50 watts per square inch or less. Standard heaters are available in 120, 208 and 240 volts. Heaters with two elements are designed for single-phase operation, while three element heaters can also be used for single-phase applications where space limitations preclude the use of a two-element heater.

Special Features Allen Head Fitting – For convenience of installation, an Allen head fitting can be furnished on a NEMA 1 outlet box. This allows installation with a 3/8″ Allen wrench rather than the wide jaw wrench required to fit the large hex nut on the NEMA 1 box. UL Listing – All standard Bottom-Mounted immersion heaters, with or without a low water cutout, are Listed by the Underwriters Laboratories under Reference E23541.

Rectangular Flange Heaters Large Diameter Elements provide extra electrical insulation for superior dielectric strength. Because elements are .475″ diameter, they are suitable for line voltages up to 600 volts. In addition, element insulation is compacted to insure uniform heat transfer from coil to sheath and all bends are repressed to insure insulation integrity in this critical area. Flanges are fabricated from 3/16″ minimum plate. Copper sheathed elements are silver soldered into brass flanges. Steel, Incoloy and stainless steel sheathed elements are welded into flanges of like materials.

Element Spacers, made from 304 stainless steel, maintain a uniform distance between elements, thus preventing hot spots where elements may otherwise touch. Terminals are 10-32 studs, spot welded to the element cold pin and insulated from the sheath with mica or silicone rubber. Elements are interconnected at the factory with copper or stainless steel bus bars. Cupped washers are furnished for field connections on heaters drawing less than 40 amps. Pressure connectors are furnished for larger heaters. Moisture-Resistant Epoxy Seals are standard on copper sheathed elements.

When the maximum fluid temperature will not exceed 250° F., epoxy seals can be furnished on steel, Incoloy and stainless heaters at no extra charge. Gaskets are furnished with each heater. A 1/16″ pressed fiber gasket is standard. Special Features Additional Elements – Up to twelve elements can be furnished in a single flange for applications where concentrated heat is required.

Special Ratings – Non-standard KW ratings and special watt densities, required for certain fluids, are available. Higher KW ratings, using longer elements, are also available. Special Sheath Materials – Monel, Inconel 600 and Type 316 stainless steel are available for use with fluids that may corrode standard sheath materials.

Compatible flange materials can also be furnished. Alternate Flange Design – Non-standard flange sizes and bolt hole locations are available to match existing installations in the field. Companion Flanges – A companion flange, made from the same material as the heater flange, is available with drilled and tapped openings matching the heater mounting holes. The companion flange is welded or brazed to the vessel, and the gasket installed between the heater flange and the companion flange. Longer Element Cold Ends – Standard cold ends are 2-1/2″ for copper, stainless and steel; 5-1/2″ for Incoloy. CSA Approval – CSA labeled units are available with construction modifications.

For more information on Special Purpose Heaters please contact us: Heatrex @ www.heatrex.com 800-243-8162